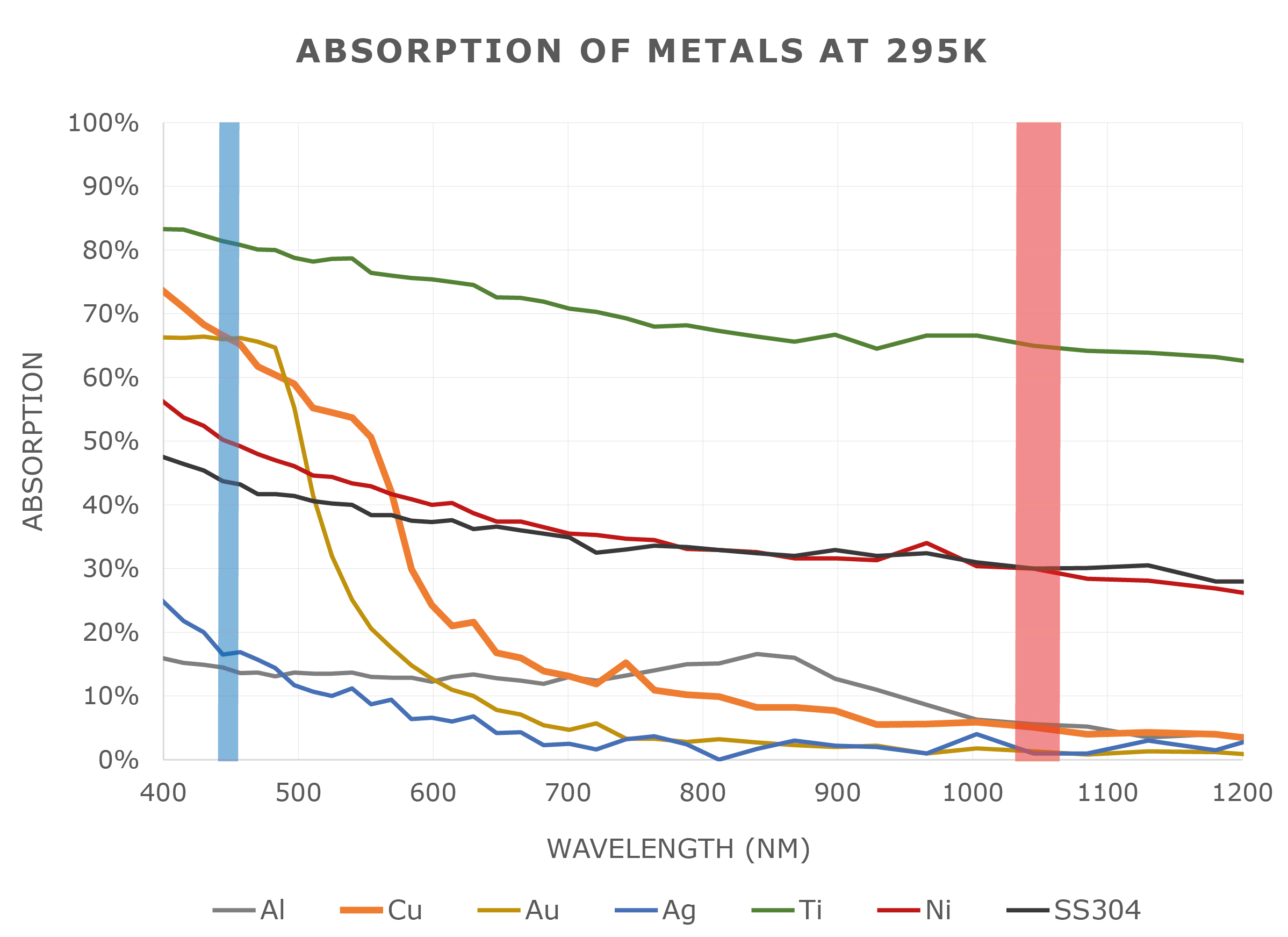

Blue high power diode laser with 200 W for material processing

Reference number: NUB-BL-Series

A revolution in material processing: the spatter-free blue diode Laser. Especially for Non-ferrous metals (copper laser welding, gold laser welding).